What is a digital twin?

A digital twin is a digital replica of a living or non-living entity.

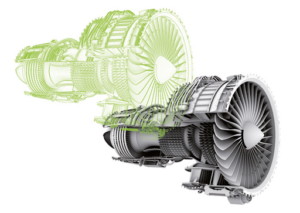

Digital twins can be virtual models of any product, process, or service and have been rapidly gaining momentum as the Internet of Things (IoT) leaps forward. This technology offers an opportunity to visualize the virtual and physical worlds together.

Digital twins are uniquely situated to help engineers develop new ideas and plan for the future. They open up new ways to gather data, monitor systems to avoid any future defects, and reduce product downtime. Digital twin technology is being used increasingly in applications ranging from aerospace to medical, automotive, manufacturing, and even urban planning sectors. It can provide greater insights to target customers by showcasing functionalities and customizations specific to the customer.

How does it work?

Digital twins act as a bridge between the real (physical) and virtual worlds. This tool allows engineers to perform simulations and try out new ideas without developing an actual product, thereby minimizing time and cost for product design and development. The technology utilizes sensors integrated with a physical system to gather data and monitor systems for any status updates on position or working condition. The gathered data can then be fed back to a cloud system for detailed analysis and feedback and used to update designs or implement changes. Any tweaks or processes tested in the virtual world can make their way into the physical world using these updates.

Why are digital twins important?

Digital twins drive performance through innovation. The ability to create proxies of the physical world will lead to better collaboration opportunities by implementing the most advanced sensors, monitoring systems, analytical and predictive capabilities. This technology opens a paradigm that will transform the future by helping us to better understand customer needs and cater to them in a connected manner. Digital Twin technology is relevant to a wide variety of applications.

Applications

As stated above, the implementation of digital twin technology can provide organizations with better insights into product performance, improve customer service, and help them make better operational and strategic decisions based on these insights. Some sectors that have been utilizing digital twins are mentioned below:

Manufacturing: Significant impact by analyzing the processes in manufacturing pipelines to make them more efficient and optimized.

Retail: Digital twins can provide security, energy optimization, and efficiency in the customer service experience. For example, by creating a digital twin for a customer, companies can provide the customer with the freedom to try clothes or accessories online or in-store.

Smartcities: City planning and implementation with Digital Twins will help enhance economic development, provide efficient management of resources, and reduce ecological footprint. It will help city planners and policymakers gain insights from various sensor networks and intelligent systems. The data will help to avoid delays and efficient service.

Automotive: Connected vehicles through digital twins will provide a personalized driving experience for the rider and lead to overall improvement in vehicle performance and efficiency.

Healthcare: Digital twins can provide assistance with personalized healthcare, including design of medical devices and their integration with the human body in a smooth manner.

Summary:

Digital Twins are part of the Industry 4.0 revolution. They change the design philosophy from “build first then tweak” to “build and tweak simultaneously” to provide better performance, unique features, and expanded functionalities. In the often autonomous world of industrial machines, the role of Digital Twins will continue evolve.